Issue #: 192

Published: November / December 2023

- Price per issue - digital : 6.50€Digital magazine

- Price per issue - print : 9.50€Print magazine

- Access to Multihulls World digital archives Digital archives

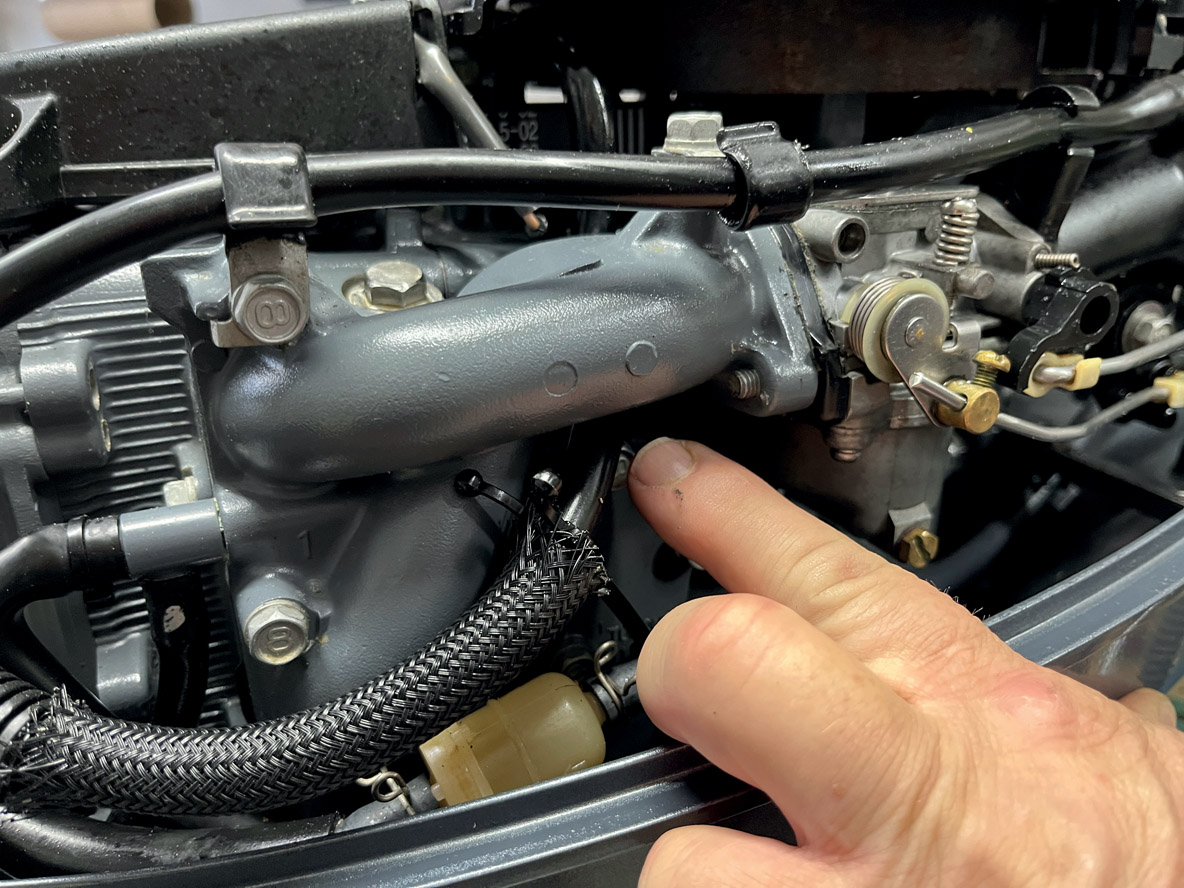

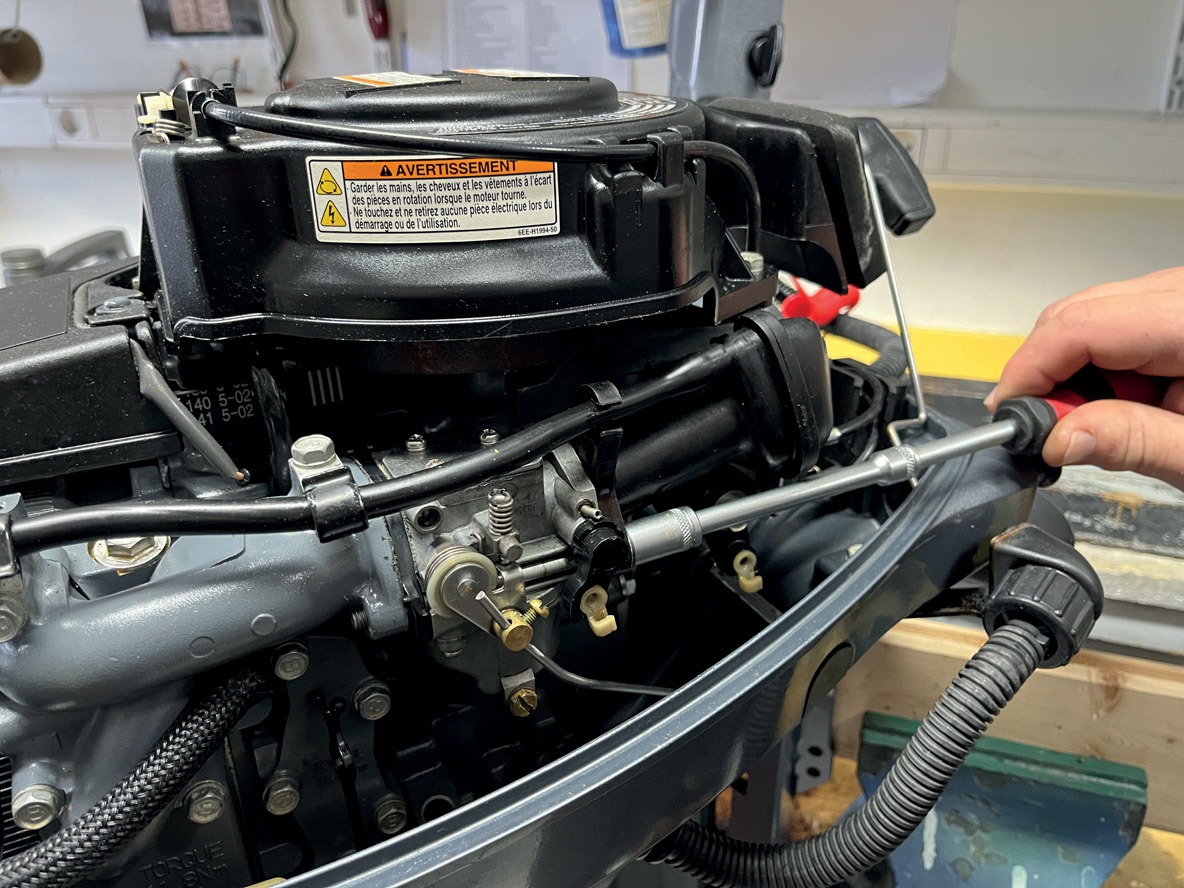

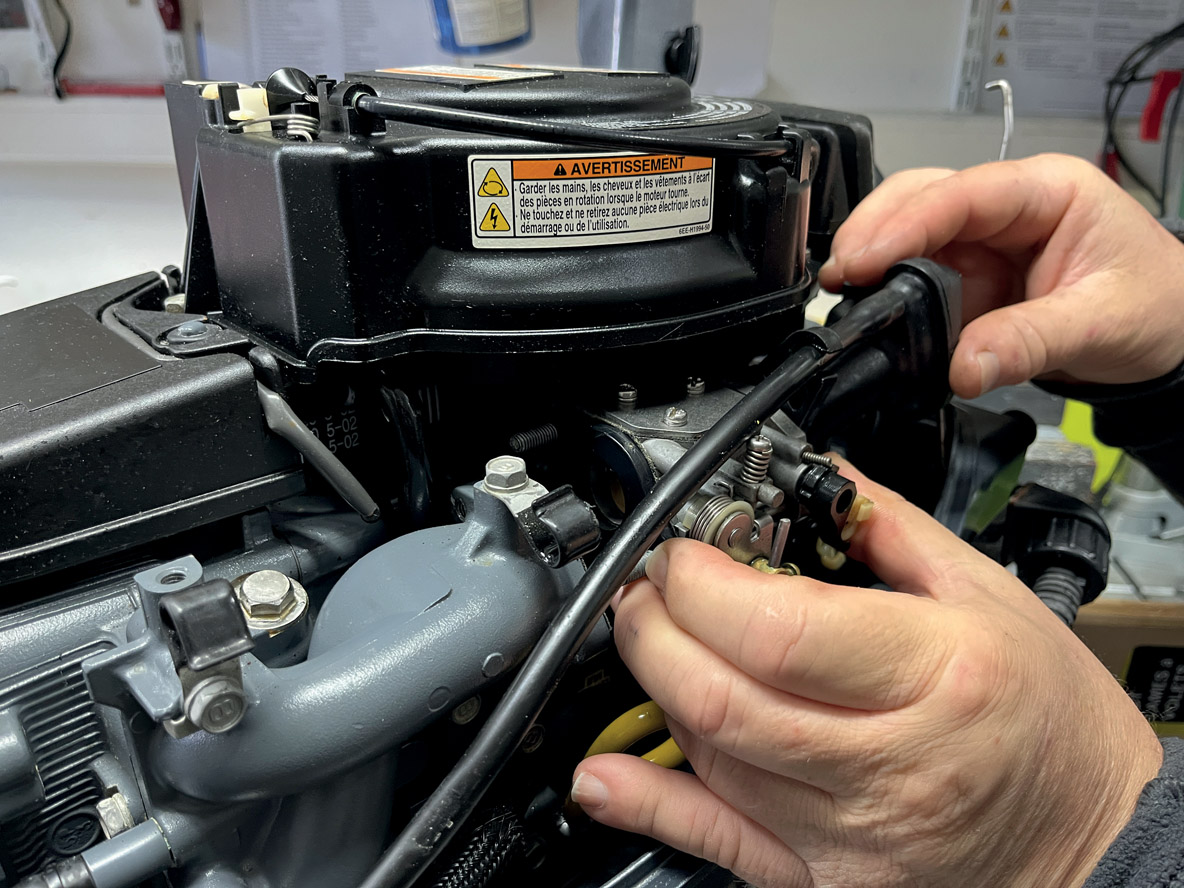

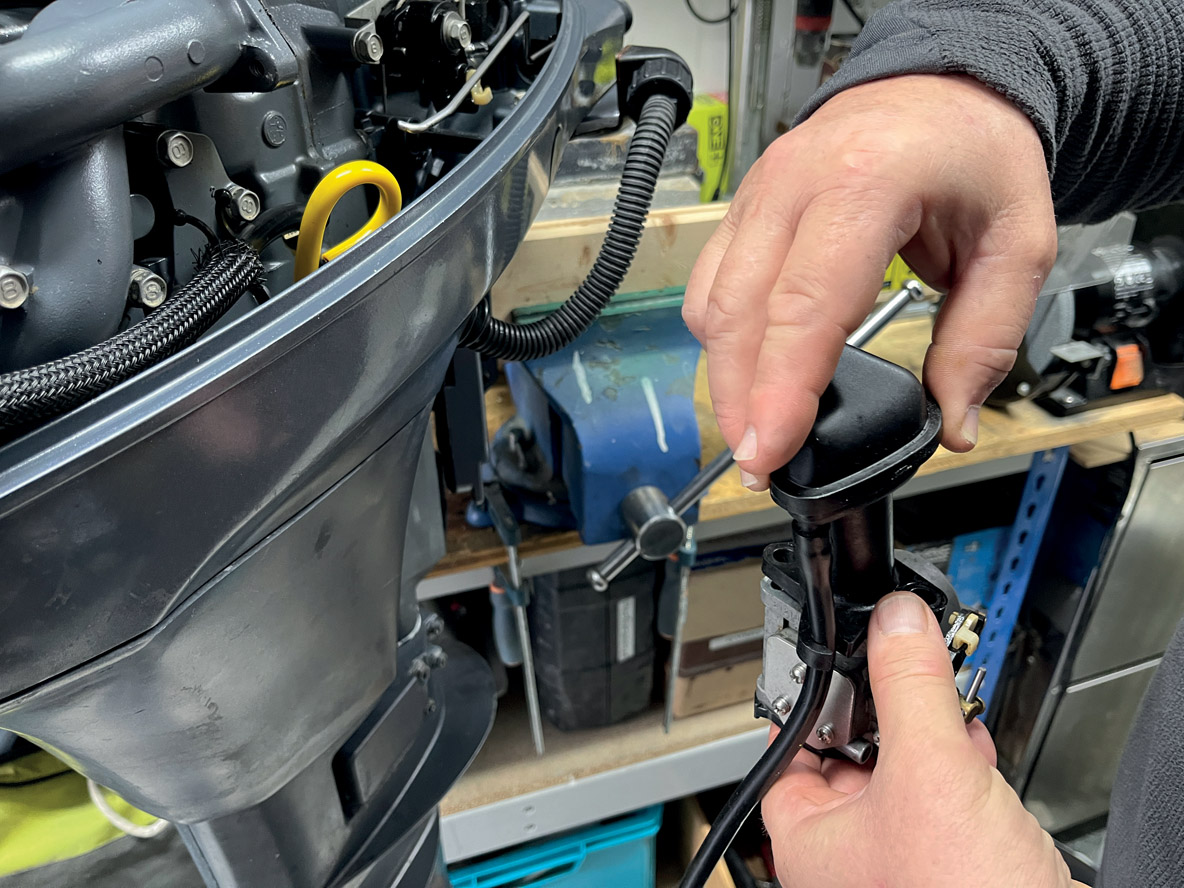

Proper maintenance of the fuel feed system can help prevent breakdowns. In this second feature on outboard motor maintenance, we’ll be taking a closer look at the traditional maintenance operations, as well as what to do in the event of mechanical failure.

What readers think

Post a comment

No comments to show.